When your AC gives out in the middle of a sweltering Arizona summer, the last thing you need is a surprise bill, right? Getting a handle on the replace ac compressor cost is your first step to getting cool again without draining your savings. Around Phoenix, you can generally expect this critical repair to fall somewhere between $1,500 and $2,800, but a few key details will shape the final number.

Breaking Down the Cost of an AC Compressor

When an HVAC technician from a company like Comfort Experts hands you a quote for a new AC compressor, that price tag covers a lot more than just the component itself. It’s a complete package that includes both the physical part and the expert labor needed to install it safely and correctly.

The compressor is often called the "heart" of your air conditioning system, and for good reason—it’s the powerhouse that circulates refrigerant to actually cool your home. Since it's such a vital and complex piece of machinery, it’s naturally one of the more expensive parts to replace.

Parts vs. Labor: What You're Really Paying For

To make sense of your quote, it helps to see how it splits into two main buckets: the part and the person. These two elements are the foundation of any compressor replacement estimate.

- The Compressor Unit (Parts): This is the cost of the new compressor itself. The price can swing quite a bit depending on your AC unit's brand, size (tonnage), and efficiency rating. A high-efficiency or variable-speed compressor will always cost more upfront than a basic, single-stage model.

- Professional Installation (Labor): This covers the technician's time, skill, and specialized tools. Swapping out a compressor isn't a quick job; it's a careful, multi-hour process that involves handling high-pressure refrigerant, something that legally requires certification.

You know what? A lot of people assume the part is the biggest chunk of the expense. In reality, skilled labor often makes up 40% to 50% of the total bill. That's because of the technical skill involved and the time it takes to do the job right without cutting corners.

To give you a clearer picture, here’s a quick summary of what those costs look like in the Phoenix area.

Average AC Compressor Replacement Costs at a Glance

This table breaks down the typical cost ranges for replacing an AC compressor in our area, showing you where your money goes.

| Expense Component | Typical Low-End Cost | Typical High-End Cost | Notes |

|---|---|---|---|

| Compressor Part Cost | $800 | $1,600 | Varies by brand, size, and efficiency (SEER2 rating). |

| Labor Cost | $600 | $1,000 | Covers 4-6 hours of certified technician time. |

| Refrigerant & Supplies | $100 | $200 | Includes refrigerant, welding materials, and system flush chemicals. |

| Total Estimated Cost | $1,500 | $2,800 | This is the all-in price you can typically expect. |

Keep in mind, these are ballpark figures. The final number can shift based on your specific system and situation.

The Big Financial Picture

Nationally, the cost to replace an AC compressor has settled in around an average of $1,200 to $2,300. For Phoenix homeowners, this is a crucial piece of info when you're weighing a major AC repair. The investment is significantly less than a full system replacement, which can run anywhere from $5,000 to $12,000. If the rest of your AC unit is in good shape, replacing the compressor is often the smarter financial move.

This gives you a solid budget to start with. While these numbers are a great starting point, other factors can definitely influence your final bill. For a broader look at repair expenses in our neck of the woods, feel free to explore our guide to AC repair costs in Arizona.

What an AC Compressor Does and Why It Matters

Let's cut right to it: your AC compressor is the heart of your entire cooling system. It’s the single most critical component, doing the heavy lifting of pumping refrigerant—the lifeblood of your air conditioner—through the system to cool your home.

When the compressor stops, the whole cooling process grinds to a halt. No exceptions.

This vital piece of equipment is tucked away inside your outdoor AC unit. Its one job is to take in low-pressure refrigerant gas and, just like the name says, compress it. This process radically increases both the pressure and the temperature of the gas.

That superheated, high-pressure gas then gets pushed into the condenser coil. The big fan in your outdoor unit blows air across these coils, and because the gas is now way hotter than the Phoenix air, it sheds its heat into the atmosphere. This is the whole magic trick: moving the heat from inside your house to the outside.

The Refrigerant's Journey

Once that heat is gone, the refrigerant transforms into a high-pressure liquid and continues its journey. This is where things get really cool—literally.

The liquid flows to an expansion valve, which acts like a tiny nozzle, causing the pressure to drop instantly. As the pressure plummets, the refrigerant rapidly expands and becomes intensely cold. Now it's a frigid, low-pressure mix, ready to do the real work of absorbing heat from your home.

Think of it like a can of compressed air. When you hold the button down, the can gets freezing cold as the pressure inside drops. The compressor and expansion valve create that same effect, but on a massive, continuous scale.

This icy refrigerant then flows through the evaporator coil inside your home (usually part of your furnace or air handler). Your system's fan blows your warm indoor air across this coil, the refrigerant soaks up the heat, and the newly chilled air is sent back through your ducts.

Why Its Health is Crucial

To complete the cycle, the compressor pulls the now-warmed refrigerant gas back in and starts the whole process over again. This constant loop is what stands between you and a sweltering Phoenix summer. A failed compressor breaks that loop, and your system is officially down for the count.

Because it operates under immense pressure and draws a ton of electricity, the compressor is by far the hardest-working part of your AC. Its health directly dictates your system's efficiency, cooling power, and your monthly energy bills. It also explains why the replace ac compressor cost is significant—it reflects both the part's complexity and the technical skill needed to install it safely and correctly.

The refrigerant it pumps is a highly specialized chemical. If you'd like to understand it better, you can learn more about what Freon is and how it works in our detailed guide. When this "heart" fails, restoring your comfort requires a professional diagnosis and a decision on the best path forward.

Recognizing the Warning Signs of a Failing Compressor

An AC compressor almost never dies in silence. It usually gives you a few distinct warnings before it gives up for good, and learning to spot them can mean the difference between a planned repair and a frantic, sweaty emergency call.

Think of it this way: your AC is trying to tell you something’s wrong. If you listen, you can get ahead of the problem and have more control over the timeline and the final replace ac compressor cost.

Strange and Unsettling Noises

One of the first and most obvious red flags comes from your outdoor unit. You know the normal, gentle hum it makes when it’s running. Anything new, loud, or jarring is a clear cry for help.

If you suddenly hear loud banging, clanking, or rattling, that’s often the sound of broken or loose internal parts—like a piston or connecting rod—bouncing around inside the compressor. A high-pitched squealing or screaming noise is even more serious. That usually points to dangerously high internal pressure, a critical issue that needs to be shut down immediately.

These are not sounds you should ever ignore. If you want to get a better handle on what’s normal and what’s not, you can learn more about why your AC is making loud noises and what each sound might signal.

It’s just like the engine in your car. A smooth hum is perfectly fine, but if it starts clanking loudly, you’d pull over right away. Your AC's compressor is the engine of your cooling system and deserves the same urgent attention to prevent a total meltdown.

Weak Airflow and Warm Air

Is the system running, but the air drifting out of your vents feels weak, or worse, isn't even cold? A struggling compressor is one of the most likely culprits.

The compressor’s whole job is to pressurize refrigerant and pump it through the system to absorb heat from your home. When it starts to fail, it loses the power to do this effectively. The result is refrigerant that isn’t getting cold enough, which means you get lukewarm air blowing through your vents. You’ll often notice the AC runs constantly but just can’t seem to hit the temperature you set on the thermostat.

Frequent Circuit Breaker Trips

Another classic sign of a dying compressor is an AC that keeps tripping its circuit breaker. The compressor is a huge motor, and it pulls a lot of electricity to get started, usually with a boost from a part called a capacitor.

As the compressor gets old and worn out, it has to work much harder to kick on. This forces it to draw more power than the circuit was ever designed for, and the breaker trips to prevent an overload. One trip might just be a fluke, but if it happens repeatedly, it’s a very strong signal that the compressor is on its last legs.

A few other symptoms to keep an eye out for include:

- Excessive Vibration: If your outdoor unit starts shaking or vibrating violently when it turns on, it could mean the compressor’s internal mechanics are damaged or the motor is struggling to start.

- Moisture or Puddles: While a little condensation is normal, if you see oily puddles or moisture actively leaking around the outdoor unit, it could be refrigerant. A refrigerant leak starves the compressor of the oil it needs for lubrication, causing it to overheat and seize up.

- Higher-Than-Normal Energy Bills: Did your power bill suddenly jump for no reason? An inefficient appliance is often the cause. A failing compressor has to run much harder and longer to do its job, which sends your energy consumption through the roof.

Catching these warning signs early gives you the chance to call a professional for a proper diagnosis before the unit fails completely. That’s far better than having it quit on you during the peak of a Phoenix heatwave.

Decoding Your Bill: What Really Drives Replacement Costs?

Ever get two quotes for an AC compressor replacement and wonder why one is $1,600 and the other is closer to $2,500? It’s a common question, and the answer isn't arbitrary. The final number on your bill is a careful sum of several distinct parts, and knowing what they are is the best way to feel confident you're getting a fair price for a critical repair.

Here’s the thing: we at Comfort Experts believe in complete transparency. So let's pull back the curtain and look at the line items that make up the total cost to replace an AC compressor.

The Compressor Part Itself

First up is the most obvious part: the new compressor. Think of it like a new engine for your car—the price varies wildly based on what you're buying. Not all compressors are created equal, and the price tag reflects that.

Here’s what influences the cost of the actual part:

- Brand and Quality: Like any major appliance, some brands are known for premium engineering and rock-solid durability, which usually costs more upfront. We stick with reliable names like Trane because our goal is a repair that lasts.

- Size (Tonnage): Air conditioners are sized in "tons" to match your home's cooling needs. A sprawling ranch home might need a powerful 5-ton unit, which requires a much beefier—and more expensive—compressor than the 2-ton unit in a small townhouse.

- Efficiency and Technology: Compressors come in a few flavors. A basic single-stage model is the most budget-friendly. A two-stage compressor runs more efficiently, and a top-of-the-line variable-speed compressor delivers the best comfort and energy savings, but also carries the highest price.

Professional Labor: The Technician's Expertise

The second big piece of the puzzle is labor. Swapping out a compressor isn’t like changing a lightbulb; it's a technical, multi-hour procedure that demands certified expertise to get right.

When you pay for labor, you're paying for a meticulous process. This includes safely recovering the old refrigerant (a step governed by strict EPA rules), physically removing the fried compressor, brazing the new one into the copper lines with perfect seals, and then pulling a deep vacuum on the system to get rid of every last trace of moisture and contaminants. It’s a job where taking shortcuts can lead to a catastrophic failure just a few months down the road.

The compressor unit itself usually accounts for 30-50% of the total replacement cost. The professional labor to install it properly typically runs between $600 to $1,200, covering the 4-6 hours needed to do the job without cutting corners.

Refrigerant Type and Refill

Your AC is a closed-loop system, and that loop is filled with refrigerant. When we replace the compressor, that refrigerant has to be managed, and the cost depends on two things:

- The Type of Refrigerant: Older systems from the early 2000s might use R-22, which was phased out for environmental reasons. It's now incredibly expensive and hard to find. Most systems today use R-410A, which is much more common and affordable.

- The Amount Needed: After the new compressor is installed, the technician has to recharge the system with the exact amount of refrigerant the manufacturer calls for—no more, no less.

To give you a clearer picture, here’s a breakdown of the main factors influencing your final bill.

Cost Factors for AC Compressor Replacement

| Cost Factor | Average Cost Range / Impact | Why It Matters for Phoenix Homeowners |

|---|---|---|

| Compressor Part | $600 – $1,800+ | Depends on size (tonnage), brand (e.g., Trane), and type (single-stage vs. variable-speed). Our extreme heat often justifies investing in a more durable, efficient model. |

| Labor | $600 – $1,200 | Covers 4-6 hours of skilled work, including refrigerant recovery, brazing, and system vacuuming. Proper installation is non-negotiable for system survival in Arizona. |

| Refrigerant | $150 – $400+ | Varies based on type (R-410A is standard; older R-22 is very expensive) and the amount needed to recharge the system to factory specs. |

| Warranty Status | Potential Savings: $600 – $1,800 | A valid parts warranty can cover the entire cost of the new compressor, leaving you to pay only for labor and refrigerant. This is a huge potential cost-saver. |

| System Access | +$100 – $300 | If your unit is on a tricky rooftop or in a very tight space, the extra time and safety measures required can add to the labor cost. |

Understanding these individual pieces helps demystify the final quote and shows you exactly where your money is going.

Warranty Status Can Be a Game-Changer

This one is huge. If your air conditioner is still covered by the manufacturer's parts warranty, the most expensive part of the job—the compressor itself—might be completely covered. Most brands offer a 5- to 10-year parts warranty.

A valid warranty can slash your out-of-pocket cost dramatically, often reducing a $2,500 job to under $1,200. You would still be responsible for labor and refrigerant costs, but having the most expensive component covered makes a massive difference. Our technicians at Comfort Experts always verify warranty status first to save you every possible dollar.

Accessibility and System Complexity

Finally, a few real-world logistics can nudge the labor cost up or down. Is your outdoor unit located on a hard-to-reach rooftop, or is it crammed into a corner behind thick landscaping? Difficult access can add to the time and effort needed to do the job safely.

Likewise, a more complex system, like a heat pump, can involve a bit more work than a standard AC-only unit. The compressor works hand-in-hand with the outdoor condenser coil; you can get more information about the cost to replace a condenser coil here to see how these major repairs relate.

Repair the Compressor or Replace the Entire AC Unit

A failed compressor puts every Phoenix homeowner at a major crossroads. Do you spend a significant chunk of money to replace just this one part, or is this the moment to upgrade your entire air conditioning system? This is a huge decision, and making the wrong call can be a costly mistake.

Honestly, there isn't a single right answer that fits everyone. But there is a clear framework you can use to make the smartest financial choice for your home. By looking at a few key factors, you can move forward with confidence, knowing you’re not just throwing good money after bad.

Age of Your Current AC Unit

The first and most important question is: how old is your air conditioner? AC units in Arizona work incredibly hard, and their typical lifespan is around 12 to 15 years. If your system is creeping up on that 10-year mark—or has already passed it—replacing just the compressor becomes a much riskier bet.

Think of it like deciding whether to put a brand-new engine in a 20-year-old car with 250,000 miles. Sure, the new engine will run great, but it’s only a matter of time before the transmission gives out or the alternator dies. An aging AC system is no different; other critical parts like the fan motor or condenser coil are likely nearing the end of their service life, too.

Repair History and Reliability

Next, think about your AC's recent track record. Has it been a reliable workhorse, or have you been calling for repairs every summer? If this compressor failure is the first major problem you've had in a decade, a targeted replacement might make perfect sense.

But if you're already on a first-name basis with your HVAC technician because of frequent breakdowns, that’s a loud and clear signal the system is in decline. Sinking more money into a unit that has become a constant source of problems is a recipe for frustration and runaway costs.

A Simple Rule for a Complex Decision

When you're looking at a big repair bill, it's easy to feel overwhelmed. Here’s a straightforward guideline that many industry experts, including our team at Comfort Experts, share with homeowners.

If the replace ac compressor cost is approaching 50% of the price of a brand-new system, and your current unit is over 12 years old, replacing the entire AC unit is almost always the better long-term financial decision.

This rule of thumb helps you avoid the trap of paying for an expensive repair today, only to face another costly breakdown next summer.

The Critical Role of Warranty and Refrigerant

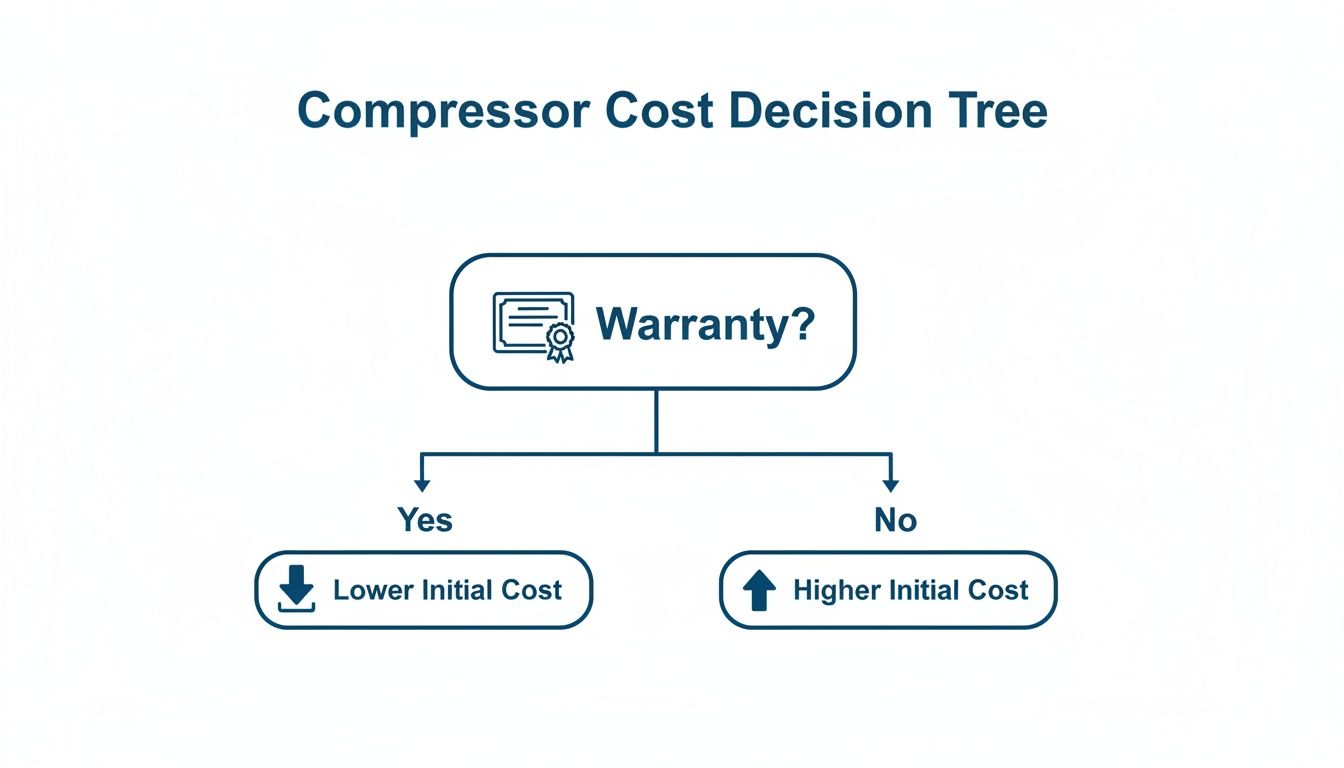

Your system's warranty status can also make the decision for you. This simple decision tree shows how a valid warranty can dramatically lower your initial out-of-pocket cost.

As the diagram shows, a warranty can make replacing just the compressor a financially sound choice by covering the most expensive part of the repair.

Finally, consider the refrigerant. If your system uses the older, phased-out R-22 refrigerant, that’s a major red flag. R-22 is now exceptionally expensive and difficult to find. Investing in a major repair for an R-22 system is often unwise, as the refrigerant alone adds a huge cost—and you're still left with an outdated, inefficient unit. Upgrading to a modern system that uses the standard R-410A refrigerant is a much smarter move.

This is also a great time to think bigger about your home's energy future. When you're facing a major HVAC decision, it can be the perfect opportunity to explore more efficient alternatives, like modern solar powered HVAC systems. Making the right choice now ensures you'll have comfort and financial peace of mind for years to come.

Why Professional Compressor Installation Is Essential

Let me explain something critical. While some home repairs make for a great weekend project, replacing an AC compressor isn't one of them. This is a complex, high-stakes job that absolutely demands specialized tools, certified training, and a deep understanding of hazardous materials.

Trying to tackle this yourself isn't just risky—it's often illegal and can lead to a catastrophic system failure. The final replace ac compressor cost includes professional installation for a reason. It’s all about protecting your safety, your system's efficiency, and its long-term reliability.

The Technical Hurdles Only a Pro Can Handle

Swapping out an AC compressor is worlds away from just unbolting an old part and dropping in a new one. It’s a meticulous, multi-step process where one tiny mistake can destroy your brand-new compressor or even your entire system.

A certified technician from Comfort Experts has the training and equipment to nail these critical tasks.

- Safe Refrigerant Recovery: The refrigerant in your AC is under extremely high pressure and is heavily regulated by the EPA. Our technicians use a specialized recovery machine to safely and legally pump every ounce of it out of the system before any work begins.

- Precise Brazing and Soldering: The new compressor has to be connected to the existing copper refrigerant lines. This requires brazing—a form of high-temperature welding—to create perfectly airtight seals that can handle hundreds of pounds of pressure without leaking.

- System Decontamination (Triple Evacuation): Once the new compressor is installed, the entire system must be purged of air and moisture. A technician uses a powerful vacuum pump to pull the system into a deep vacuum, boiling off any contaminants that would otherwise turn into corrosive acid and eat your new compressor from the inside out.

A common DIY mistake is failing to pull a proper vacuum on the system. Even a tiny amount of moisture left in the lines will mix with the refrigerant and oil, creating a sludge that grinds down internal components and leads to a second, premature failure.

Protecting Your Warranty and Your Investment

Beyond the technical side, hiring a professional is the only way to protect your financial investment. Nearly all HVAC manufacturers require their equipment to be installed by a licensed and certified technician.

If you attempt a DIY installation, you will immediately void the parts warranty on your new compressor. If it fails a month later because of a small installation error, you're on the hook for the full cost of another one.

Hiring a reputable company also means you’re protected by our liability insurance. If something goes wrong during the repair, you won't be held financially responsible. Choosing the right contractor is crucial, and if you need some pointers, our guide on how to choose an HVAC company has some valuable tips.

Ultimately, professional installation isn't just a line item on an invoice; it's peace of mind and an insurance policy for your home's most important appliance.

Your Next Steps for a Reliable AC Repair

Okay, so dealing with a broken AC compressor, especially when a Phoenix summer is breathing down your neck, is nobody's idea of fun. But now you're armed with the right information. You know what to look for, you understand what goes into the final bill, and you have a solid framework for deciding between repair and replacement.

The next move is turning that knowledge into a lasting fix.

Getting a trustworthy, accurate quote is everything. The only way to get a real, no-surprises price for your replace ac compressor cost is for a certified technician to do a proper, hands-on diagnostic of your system. This isn't just a quick peek—it's a deep dive to confirm the compressor is the real problem and to hunt for any underlying issues that caused it to fail in the first place.

Get a Professional and Transparent Diagnosis

A good diagnosis is the bedrock of a good repair. A skilled tech won't just confirm the compressor is shot; they'll check the capacitor, contactor, refrigerant charge, and other critical parts. This makes sure you’re fixing the root cause, not just slapping a bandage on a symptom that's bound to pop up again.

This professional check-up gives you two incredibly important things:

- An Accurate Quote: One based on the specific part your system needs, the health of its supporting components, and your warranty status.

- Clear Options: The technician can lay out the repair cost side-by-side with a full system replacement, giving you all the data you need to make the smartest financial decision for your home.

Why a Quick Fix Isn't the Answer

When your house is heating up, it's tempting to jump at the cheapest or fastest option. But a compressor replacement is one job where cutting corners is a recipe for a much bigger headache later. A sloppy installation can cause immediate failure, void your warranty, and cost you way more in the long run.

Investing in a professional diagnosis and installation from a licensed, insured, and reputable company is your best defense against repeat problems. It’s the difference between a temporary patch and a permanent fix that restores your comfort and peace of mind for years to come.

Beyond getting the immediate repair handled right, adopting smarter energy habits can make your home more efficient and comfortable. Taking a look at these proven HVAC and energy tips for lowering your electric bill in summer can help you maximize your savings. When you combine a quality repair with a proactive mindset, you're set up for long-term success.

Choosing the right partner for this job makes all the difference. You need a team that’s honest, stands behind their work, and gets how urgent a dead AC is in Arizona. That’s where we come in.

For an honest assessment and fair pricing on your AC compressor replacement, trust the team at Comfort Experts. We know AC problems don’t keep business hours, which is why we're here to help when you need us most. Call us today at 480-207-1239 or schedule service online for a prompt and professional solution.